As a high-precision feeder specially adapted to the use of high-speed punch presses, the clip feeder will inevitably have defects due to imp...

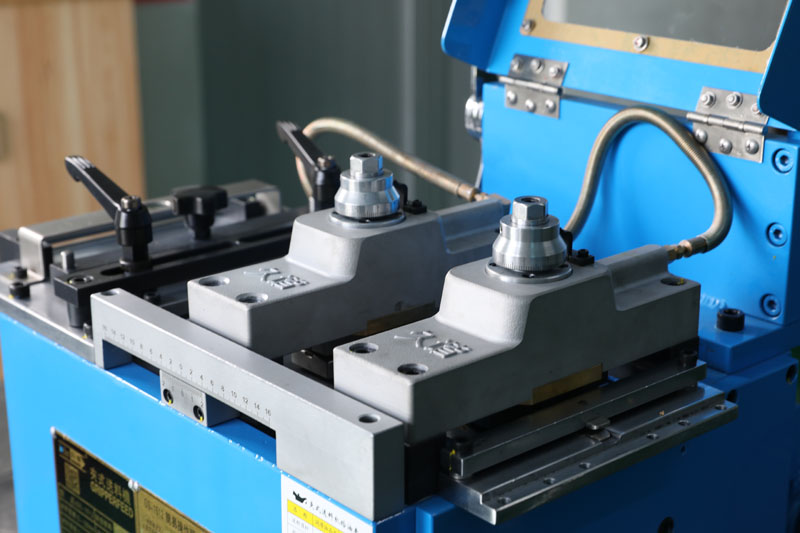

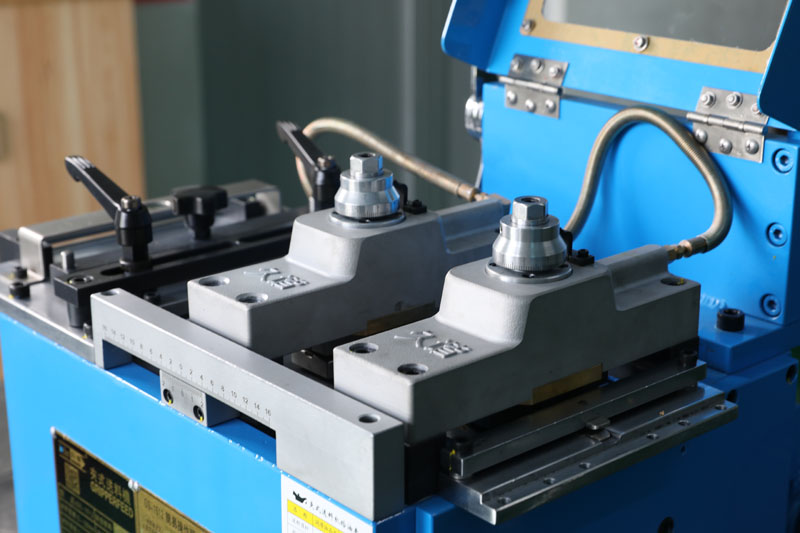

The biggest difference between the mechanical NC feeder and the pneumatic NC feeder is the way of relaxation. The mechanical NC uses a mecha...

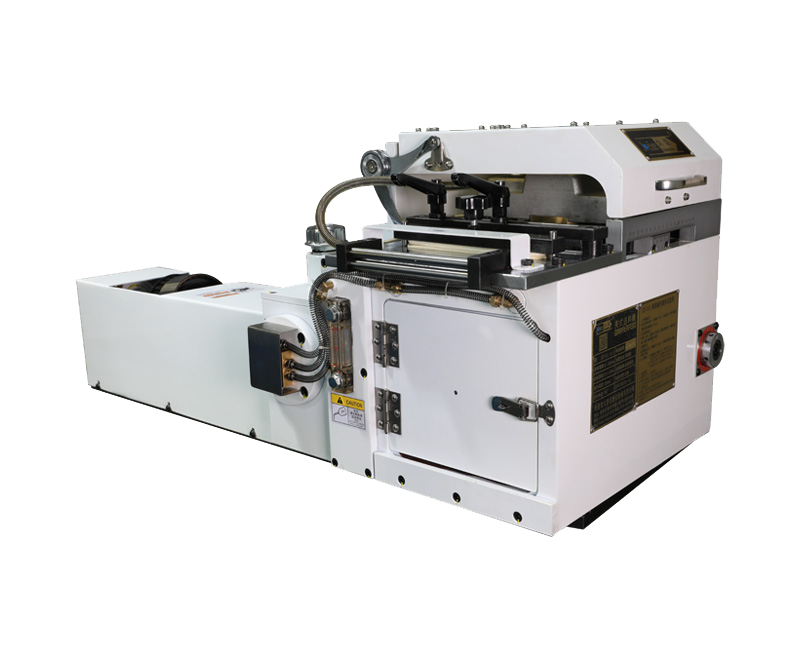

The three-in-one feeder is divided into three types: standard, medium and thick plates, which are distinguished according to the thickness o...

Air feeder: The air feeder is the earliest feeding equipment used in the stamping industry. Its principle is to use the air source as the po...

202007/03

In addition to the conventional automatic feeding method of the machine device at the mold inlet and the method of the machine device being forced to pull the material at the die outlet, the long-punch feeder can also install two punch feeders in the Special o...

202007/03

The large deflection data rack with deflection NC servo feeder is the model planned for the large deflection falling round stamping production line. It is mainly used for the automatic stamping of large wafers. It has efficient punching of wafers and saves dat...

202007/03

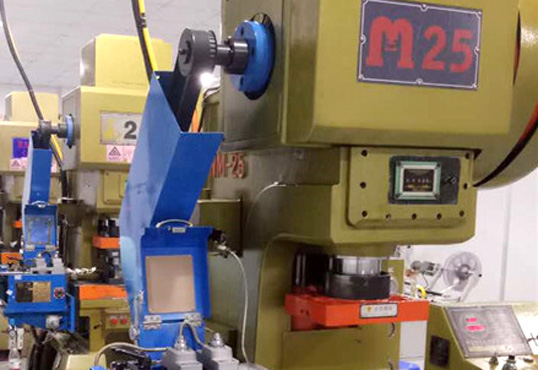

The production of stamping is moving towards high speed and high precision. There are more and more occasions where high-speed punching is used during stamping production. The maximum number of strokes of high-speed punching machine can reach 1200 times/min. A...

202007/03

The active feeder is used as a machine to transmit data. Occupation is very wide, and it is one of the necessary equipment in light industry and heavy industry.

202006/23

Because different materials are transported with different reference ratios, if the powder is transported, the load of this material to the feeder is small, and the corresponding material transport speed will also be improved. When other punch feeders are proc...

202006/23

Before the selection, we first need to know whether the stamping products are suitable for the active feeder. This depends on the production process of the integrated product. Whether the original data can be turned into a coil, the output of the product is th...

202006/23

After we have decided to buy a punch feeder, we should go to some large-scale factories to buy the punch feeder. The main specifications should match the processing size of the workpiece. The feeder manufacturer information is for high-tech industries. Coming,...

202006/23

As a high-precision feeder specially adapted to the use of high-speed punch presses, the clip feeder will inevitably have defects due to improper operation, incorrect debugging, machine wear and other factors in the practice process.

202006/23

The biggest difference between the mechanical NC feeder and the pneumatic NC feeder is the way of relaxation. The mechanical NC uses a mechanical rod to relax (requires a device to relax the rod on the punch slider), which relaxes quickly and does not crush th...

202006/23

The three-in-one feeder is divided into three types: standard, medium and thick plates, which are distinguished according to the thickness of the applicable data. The standard three-in-one feeder is suitable for the automatic production of 0.3-2.2mm thick thin...

202006/23

Air feeder: The air feeder is the earliest feeding equipment used in the stamping industry. Its principle is to use the air source as the power, clamp the material through the cylinder

202006/23

Whether it is light industry or heavy industry, the feeder is not a short mechanical auxiliary equipment. It is used to transport materials. It is a kind of basic equipment. With the development of technology, the machine has also been greatly updated. Nowaday...

202006/23

The three-in-one feeder is a highly efficient feeding equipment developed for the stamping industry. It is a three-in-one machine that uses raw materials as rolling materials

202006/23

Stamping forming is an important forming method in modern manufacturing industry, which is widely used in industries such as cars, aerospace and shipbuilding. Then in the stamping process, there are many technical problems, and the data of many high-tension pl...

202006/23

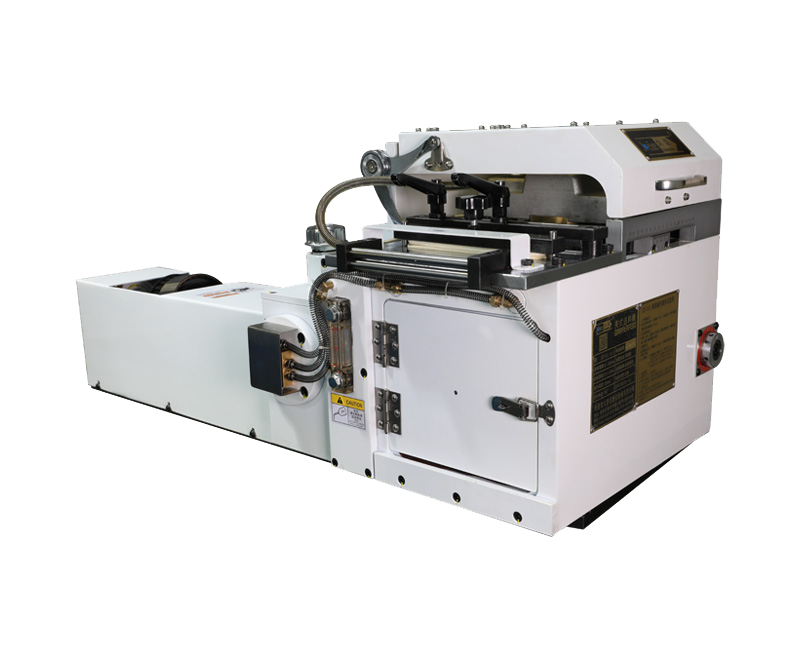

The high-speed roller feeder is the most widely used feeder in China with traditional punches, pneumatic fine punches, and high-speed punches. It has the advantages of low failure rate, no energy consumption, high degree of automation, and good stability.

202006/23

The high-speed punching machine is the most commonly used production equipment for sheet metal processing. Its punching speed is fast. If the traditional single-punch processing technology is used, it will not fully exert its own value of efficient processing....

202006/23

CNC punch feeder is a kind of mechanical equipment used in conjunction with CNC punch press. It can be accurately positioned and fed after programming, making the processing of sheet metal parts easier, allowing the mechanical processing to be completely separ...

Follow us

+86 13580817073

+86 13580817073